Direct Part Marking

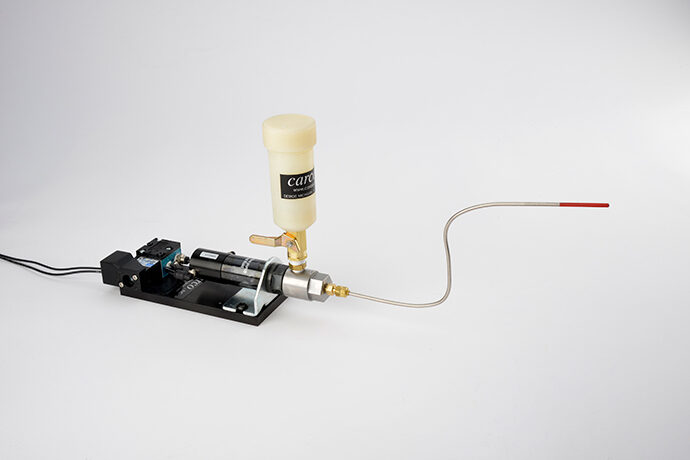

Our direct automotive part marking solutions are designed for neat and repeatable identification. Our contact markers provide a non-atomized, repeatable dot that can adhere to the components’ surface and mark 10,000 to 20,000 parts for every two ounces of marking fluid.

Our direct part marking products include the ES-612 Spring Marker, ES-712-S Automated Assembly Spring Marker, ES-1518 Mini-Contact, ES-2618 Mini-Contact Marker, and ES-1752 Mini-Contact.

The ES-612 is our original direct contact marker. It’s available in a range of options, making it an extremely versatile product for many applications.

The ES-712-A is fast-drying and has an optional magnetic reed cylinder.

Ideal for tight-fitting applications, the ES-1518 uses a dual-action air cylinder with a one-half to 4-inch stroke and multiple marking heads.

The ES-2618 was designed for high-accuracy applications with mounting constraints. It employs a dual-acting air cylinder for improved precisions and comes with one-eighth, one-fourth, and half-inch marking heads.

The ES-1752 is a compact marking solution available in multiple stroke lengths incorporating a single-action spring return for ease of use. Users can choose between one-eighth, one-fourth, and half-inch marking heads, which can easily be mounted to accommodate any part configuration.