About

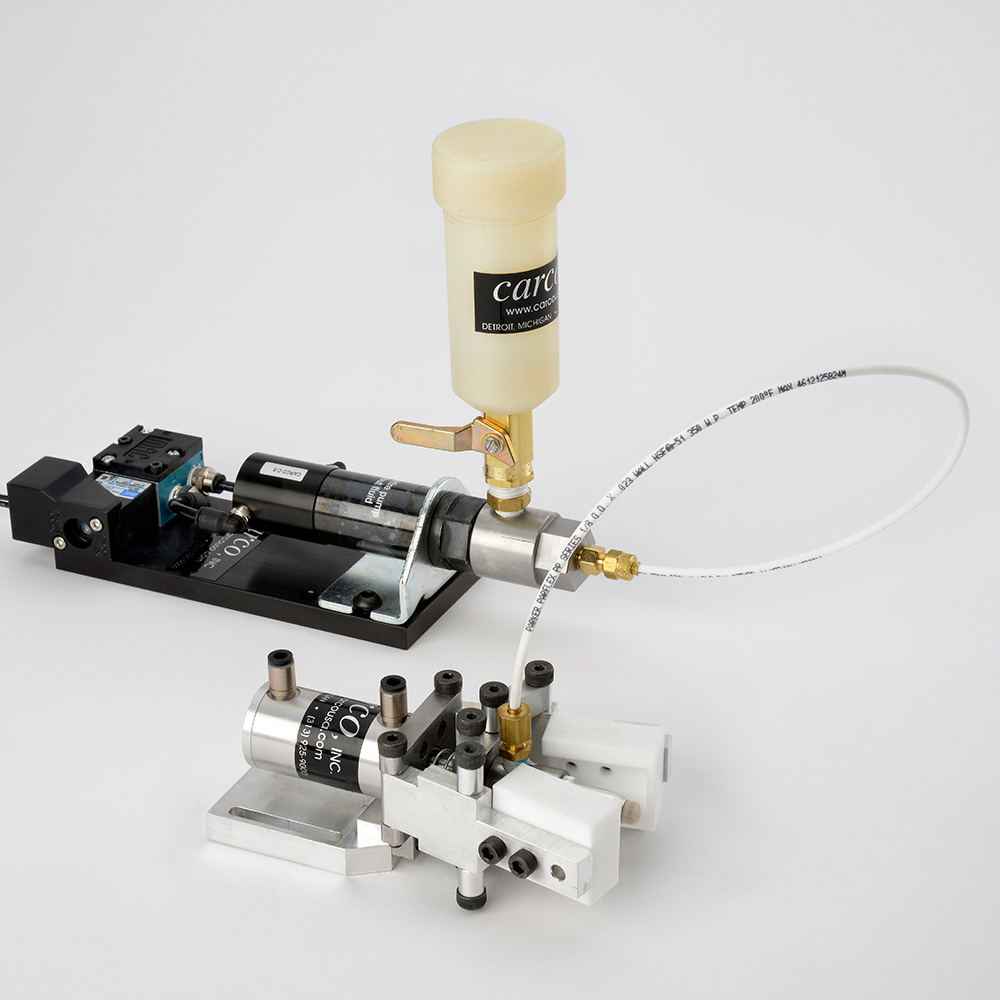

Our ES-2618 Automated Mini-Contact Marker is designed to reliably put neat, clean ink marks on a surface upon demand and provide the same function and reliability as our ES-712 marker.

Features

This marker is best used where there are mounting constraints. The ES-2618 cover assembly allows for the use of fast-drying marking fluids and uses a double acting air cylinder for maximum control and precision. Available in 1/8”, 1/4″, and 1/2” marking heads and 1.5” to 4” cylinder stroke lengths. Marking head assembly can be mounted in any orientation. The fully extended ES-2618 is half the length of the retracted ES-712.