Carco offers a wide range of highly accurate part marking systems and ink for many metal, pipe, and tubing manufacturing applications. Our non-contact systems are best for marking metals and tubular products due to their capability in working with fast-drying inks and withstanding harsh environments.

The ES-1157 Carco Jetshot, ideal for marking fast-moving materials in harsh industrial environments, offers economical ink usage and adaptable “Jetshot” Tubes for precise, low-maintenance marking in metal, pipe, and tubing manufacturing. Its robust design allows for easy mounting in any orientation, ensuring seamless integration into various production lines.

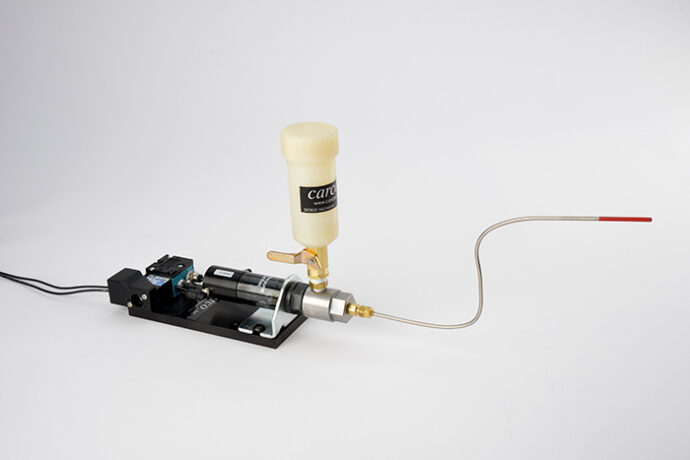

The Carco ES-800 spray unit is an efficient solution for applications requiring small, controlled spots, capable of marking on dry, wet, absorbent, or oiled surfaces. Its integration with NDT and Eddy-Current testing units makes it ideal for identifying rejected material. The ES-800 is available with a 3” or 6” extension, enhancing its versatility for marking hard-to-reach areas.

The Carco ES-1010 Low-Pressure Spray System offers precise and continuous marking with minimal overspray at 5-15 PSI. Its adaptability makes it ideal for creating distinct lines or spots on moving metal surfaces, and the system’s capacity to produce various mark sizes caters to the specific needs of metal, pipe, and tubing production processes.